General

- This specification covers the requirements for the supply of single-mode optical fiber cables.

- The single mode optical fiber cable comply with the requirements of this specification and generally meet any latest relevant ITU-T Recommendation G.652D YOFC brand

Fiber characteristics

Geometric characteristics

| Item | Item | ||

| Mode field diameter | At 1310nm | 9.2±0.4μm | |

| Cladding diameter | 125±1μm | ||

| Core concentricity error | ≤0.6μm | ||

| Cladding non-circularity | ≤1.0% | ||

| Cut-off wavelength (λcc) (for cable) | ≤1260nm | ||

| Cut-off wavelength (λc) (for fiber) | 1180nm~1330nm | ||

| Primary coating diameter | (Not included color layer) | 245±10μm | |

| (Included color layer) | 250±15μm | ||

| Coating-cladding concentricity error | ≤12.5μm | ≤12.5μm | |

| Fiber curl radius | ≥4m | ≥4m | |

Transmission characteristics

| Item | Item | ||

| Attenuation | At 1310nm | ≤0.34dB/km | |

| At 1550nm | ≤0.19dB/km | ||

| Macro bending loss | Φ=60mm, 100turns at 1550nm | ≤0.1dB | |

| Chromatic dispersion | Within 1288~1339nm | ≤3.5ps/nm·km | |

| At 1550nm | ≤18ps/nm·km | ||

| Zero dispersion wavelength | 1300~1324nm | Zero dispersion wavelength | |

| Zero dispersion slope | ≤0.092ps/nm2·km | Zero dispersion slope | |

Optical Fiber Cable

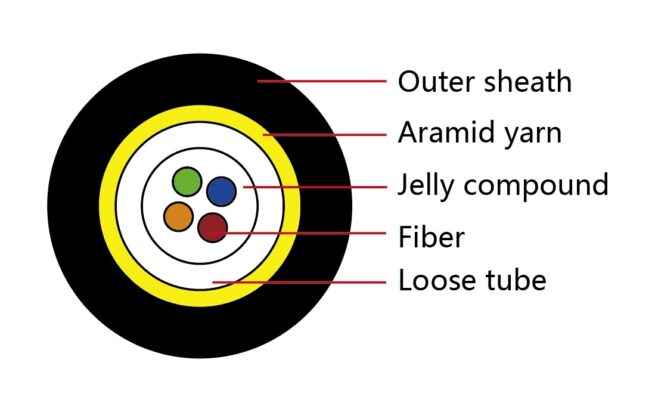

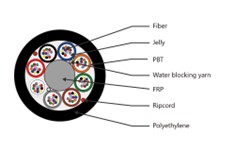

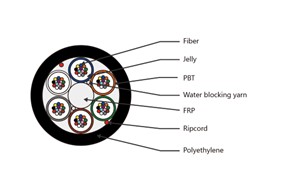

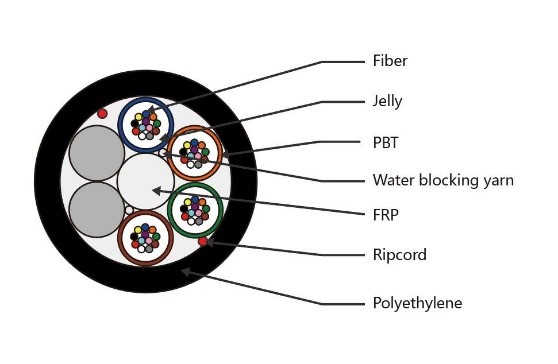

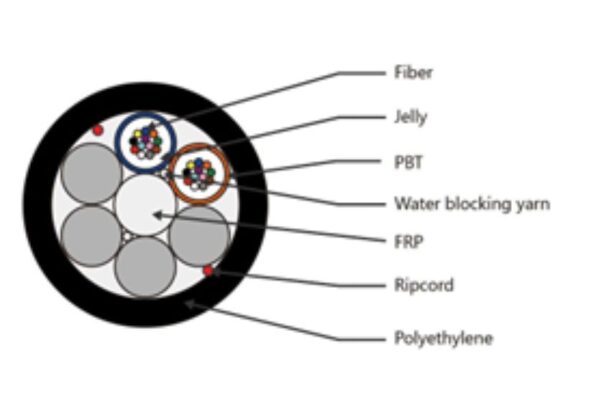

Cross section

Technical Characteristics

The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

- The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties

- Multiple water blocking material filling provides dual water blocking function

Construction:

- Outer sheath (HDPE, Black)

- Loose tube

- Fiber and jelly

- Central strength member (FRP)

- Water blocking yarn

- Rip cord*1

| Fiber count | 24F | 48F | 72F | 96F | 144F | ||||

| Model Number | TGT-MY2H1-24 | TGT-MY2H1-48 | TGT-MY2H1-72 | TGT-MY2H1-96 | TGT-MY2H1-144 | ||||

| No of loose tube / filler | 2/4 | 4/2 | 6/0 | 8/0 | 12/0 | ||||

| Fiber No. per tube | 12 | ||||||||

| Loose tube diameter | 1.5±0.1mm | ||||||||

| Central strength member diameter | 1.6±0.1mm | 1.6±0.1mm | |||||||

| Outer sheath thickness | Nominal 0.45mm | Nominal 0.45mm | |||||||

| Cable OD | 5.6mm | Cable OD | 5.6mm | ||||||

| Cable weight | 26kg/km | Cable weight | 26kg/km | ||||||

| Operation temperature range | -20 deg C to + 70 deg C | ||||||||

| Installation temperature range | -10 deg C to + 50 deg C | ||||||||

| Transport and storage temperature range | -20 deg C to + 70 deg C | ||||||||

| Tensile load | 550N | ||||||||

| Crush resistance: short/long term(N/10cm) | Short term:500;Long term:200 | ||||||||

| Minimal installation bending radius | 20 x OD | ||||||||

| Minimal operation bending radius | 10 x OD | ||||||||

Color code scheme

| Fiber color | blue | orange | green | brown | grey | white | red | black | yellow | violet | pink | aqua |

| Tube color | blue | orange | green | brown | grey | white | red | black | yellow | violet | pink | aqua |

TEST LIST

Tension Loading Test

| Test Standard | IEC 60794-1-2 E1 |

| Sample length | No less than 50 meters |

| Load | tension load |

| Duration time | 1 minute |

| Test result | Additional attenuation:≤0.1dB after test |

| No damage to outer jacket and inner elements |

Crush/Compression Test

| Test Standard | IEC 60794-1-2 E3 |

| Load | Max. crush load |

| Duration time | 1 minute |

| Test number | 3 |

| Test result | Additional attenuation:≤0.1dB after test |

| No damage to outer jacket and inner elements |

Impact Resistance Test

| Test Standard | IEC 60794-1-2 E4 |

| Impact energy | 1J |

| Radius | 300mm |

| Number of impacts | One in 3 different places spaced not less than 500 mm apart |

| Test result | No damage to outer jacket and inner elements |

Torsion/Twist Test

| Test Standard | IEC 60794-1-2 E7 |

| Sample length | 1m |

| Angles | ±180 degree |

| cycles | 10 |

| Test result | Additional attenuation:≤0.1dB after test |

| No damage to outer jacket and inner elements |

Bend Test

| Test Standard | IEC 60794-1-2 E11A |

| Mandrel radius | 20 X diameter of cable |

| Turn number | 4 |

| Number of cycles | 3 |

| Test result | No damage to outer jacket and inner elements |

Repeated Bending Test

| Test Standard | IEC 60794-1-2 E6 |

| Bending radius | 20 X diameter of cable |

| Cycles | 25 cycles |

| Test result | Additional attenuation:≤0.1dB after test |

| No damage to outer jacket and inner elements |

Temperature cycling Test

| Test Standard | IEC 60794-1-2 F1 |

| Temperature step | +20℃ →-20℃ →+70℃→20℃ |

| Time per each step | 12 hrs |

| Cycles | 2 |

| Test result | Attenuation variation for reference value (the attenuation to be measured before test at +20±3℃) ≤ 0.15dB/km @1550nm and reversible |

Water penetration Test

| Test Standard | IEC 60794-1-2 F5 |

| Height of water column | 1m |

| Sample length | 3m |

| Test time | 24 hrs |

| Test result | No water leakage from the opposite of the sample |

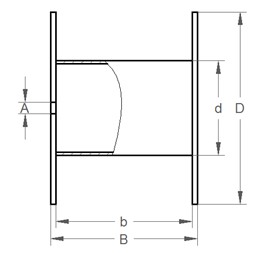

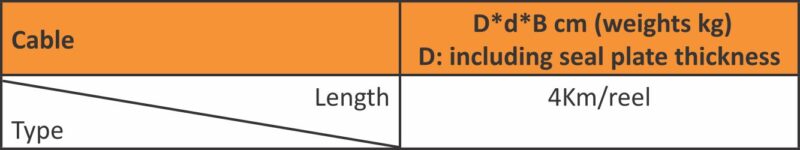

PACKING AND DRUM

Our cables are coiled on wooden drum. During transportation, right tools should be used to avoid damaging the package and to handle with ease. Cables should be protected from moisture; kept away from high temperature and fire sparks; protected from over bending and crushing; protected from mechanical stress and damage.

Wooden Drum

(The barrel core is a metal structure)

Note: The drum size & cable weight as above is estimated and final size & weight shall be confirmed before shipment.

The inner end and the outer end of cable are equipped with heat shrinkable end cap and the drum protected with strong wooden batten.

Part No

Core Type

No of Cores

OD-mm

TGT-MY2H1-24

YOFC-G652D

24

5.6±0.2

TGT-MY2H1-48

YOFC-G652D

48

5.6±0.2

TGT-MY2H1-72

YOFC-G652D

72

5.6±0.2

TGT-MY2H1-96

YOFC-G652D

96

7±0.2

TGT-MY2H1-144

YOFC-G652D

144

7.8±0.2