General

This specification presents the characteristics of air-blown cable. The cables and corresponding fiber optics are all compatible with latest relevant ITU recommendation for G.652D. The cable structure is well-designed to be installed inside micro ducts, thanks to the improved sheath used as the cable coating.

Fiber characteristics

Optics Specifications

Attenuation(dB/km)

@1310nm

≤0.34db/km

@1383nm (after hydrogen aging)

≤0.32db/km

@1550nm

≤0.20db/km

@1625nm

≤0.24db/km

Dispersion

@1285nm~1340nm

-3.0~3.0ps/(nm*km)

@1550nm

≤18ps/(nm*km)

@1625nm

≤22ps/(nm*km)

Zero-Dispersion wavelength

1300~1324nm

Zero-Dispersion slope

≤0.092ps/(nm2*km)

Mode field diameter @ 1310nm

9.2±0.4μm

Mode field diameter @ 1550nm

10.4±0.8μm

PMD

Max. value for fiber on the reel

0.2ps/km 1/2

Max. Designed value for link

0.08ps/km 1/2

Cable cutoff wavelength cc

≤1260nm

Effective group index(Neff)@1310nm

1.4675

Effective group index(Neff)@1550nm

1.4680

Macro-bend loss(Φ60mm,100 turns)@1550nm

≤0.05db

| Back scatter characteristic (@1310nm&1550nm) | ||

| Point discontinuity | ≤0.05db | |

| Attenuation uniformity | ≤0.05db/km | |

| Attenuation coefficient difference for bi-directional measurement | ≤0.05db/km | |

| Geometrical characteristics | ||

| Cladding diameter | 125±1μm | |

| Cladding non-circularity | ≤1% | |

| Core/cladding concentricity error | ≤0.4μm | |

| Fiber diameter with coating(uncolored) | 245±5μm | |

| Cladding/coating concentricity error | ≤12.0μm | |

| Curl | ≥4m | |

| Mechanical characteristic | ||

| Proof test | 0.69GPa | |

| Coating strip force(typical value) | 1.4N | |

| Dynamic stress corrosion susceptibility parameter(typical value) | ≥20 | |

| Environmental characteristics (@1310nm&1550nm) | ||

| Temperature induced attenuation(-60~+85℃) | ≤0.5dB/km | |

| Dry heat induced attenuation(85±2℃,30days) | ≤0.5dB/km | |

| Water immersion induced attenuation(23±2℃,30days) | ≤0.5dB/km | |

| Damp heat induced attenuation(85±2℃,RH85%,30days) | ≤0.5dB/km | |

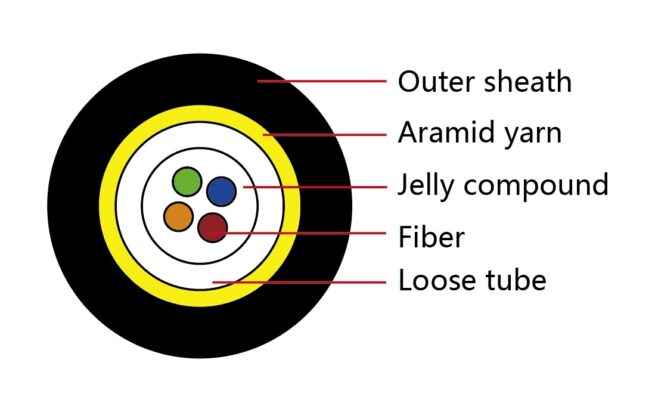

OPTICAL FIBER CABLE

Cross section

| No. of cable | 6 | 12 | 24 | ||||

| Fiber Model | YOFC G 652D | ||||||

| Loose Tube | Material | PBT | |||||

| Diameter (±0.1) mm | 1.6 | 2.4 | |||||

| Thickness (±0.03) mm | 0.2 | 0.35 | |||||

| Strength Member (Material) | Aramid Yarn | ||||||

| Low Friction | Material | HDPE | |||||

| Thickness (±0.1) mm | 0.3 | 0.5 | |||||

| Cable Diameter (±5%) mm | 2.3 | 3.0 | |||||

| Cable Weight (±10%) kg/km | 5.0 | 8.0 | |||||

| Attenuation | 1310nm | ≤0.36dB/ km | ≤0.36dB/ km | ≤0.36dB/ km | |||

| 1550nm | ≤0.22dB/ km | ≤0.22dB/ km | ≤0.22dB/ km | ||||

| Min. bending | Without Tension | 10.0×Cable-φ | 10.0×Cable-φ | 10.0×Cable-φ | |||

| Under Maximum | 20.0×Cable-φ | 20.0×Cable-φ | 20.0×Cable-φ | ||||

| Temperature range (°C) | Tension | -20~+60 | -20~+60 | -20~+60 | |||

| Transport & Storage | -40~+70 | -40~+70 | -40~+70 | ||||

| Operation | -40~+70 | -40~+70 | -40~+70 | ||||

The fibres shall be marked by a coloured coating with 12 different colors following the standard EIA/TIA598 as below: (Fiber cores with more than 12 cores are identified by dots.)

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Blue | Orange | Green | Brown | Grey | White | Red | Nature | Yellow | Violet | Pink | Aqua |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| Blue | Orange | Green | Brown | Grey | White | Red | Black | Yellow | Violet | Pink | Aqua |

Performance

| NO | ITEM | TEST METHOD | SPECIFICATION |

| 1 | Tensile performance IEC60794-1-21-E1 | -Short-term load:20N | Loss change ≤ 0.10 dB@1550 nm (after test) – Fiber strain ≤ 0.60 % – No sheath damage |

| 2 | Crush test IEC60794-1-21-E3 | – Time: 5 minute | Loss change ≤ 0.10 dB@1550 nm (during test) – No sheath damage |

| 3 | Repeated bending IEC60794-1-21-E6 | – Bending radius.: 20 × D – Load: 25N – Flexing rate: 2sec/cycle – No. of cycle: 25 | – No fiber break – No sheath damage |

| 4 | Water penetration IEC60794-1-22-F5 | – Height of water: 1m – Sample length: 3 m – Time: 24 hr | – No drip through the cable core assembly |

| 5 | Twist IEC60794-1-21-E7 | – Length: 1 m – Load: 40N – Twist rate: ≤60sec/cycle – Twist angle: ±180° – No. of cycle: 5 | Loss change ≤ 0.10 dB@1550 nm (during test) – No sheath damage |

| 6 | Temperature Cycling IEC60794-1-22-F1 | – Temperature step: +20oC→-20oC→+70oC→+20oC – Number of cycle: 2 turns – Time per each step: 12 hrs | – Loss change ≤ 0.15dB/ km@1550 nm (during test) – Loss change ≤ 0.05dB/ km@1550 nm (after test) – No sheath damage |

D*: Cable diameter

SHEATH MARKING

Manufacturer Cable type Manufacturing year ID Length marking in feet or meter.

PACKING AND DRUM

The cables are packed in carton, coiled on Bakelite & Fumigated wooden drum. During transportation, right tools should be used to avoid damaging the package and to handle with ease. Cables should be protected from moisture; kept away from high temperature and fire sparks; protected from over bending and crushing; protected from mechanical stress and damage. Packing length: 2km/reel-4km/reel.

ORDERING INFORMATION

| Part No | Core Type | No of Cores | OD-mm |

| TGT-MY2L1-06 | YOFC-G652D | 6 | 2.3 ± 0.2 |

| TGT-MY2L1-12 | YOFC-G652D | 12 | 2.3 ± 0.2 |

| TGT-MY2L1-24 | YOFC-G652D | 24 | 3.0 ± 0.2 |